Far East have been designing and building extraction systems for over 30 years, with experience of the unique high-temperature, high-grease, high-vapour environment of stir-fry cooking.

We’ve earned a reputation with local authorities’ planning department for delivering vent/extract systems that can meet stringent noise, odour and visual intrusion requirements.

Our engineers calculate the air volume change required and model air flow through the kitchen using DW172. This ensures the fan is powerful enough to remove fumes without excessive noise, odour or draughts and “make-up” supply air is sufficient.

We fabricate the canopy and ducting in our UK factory before installing on-site. Our canopy hoods are available with integral fluorescent or LED lighting. Canopies are now required to overhang all cooking appliances by 300 mm.

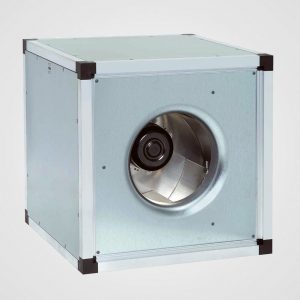

Although more expensive, we normally fit centrifugal fans because:

- They cope well with the high air pressure and resistance typical of kitchen extract

- They are more reliable because the large gap between the fan blades and case prevents grease build-up stopping the fan turning

- The insulated side panels reduce noise and are easily removed for cleaning

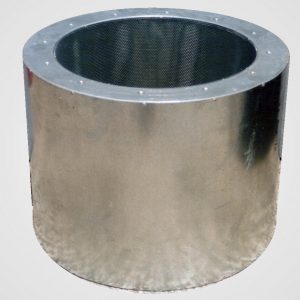

Mesh filter

- Fitted in canopy and remove more grease than baffle filters.

- Air resistance is higher than baffle filters.

- Can become a fire hazard if not regularly cleaned.

- Not permitted on new installations because of fire risk.

Baffle filter

- Fitted in canopy and remove most of the grease, which runs in to collection pots.

- Has lowest air resistance.

- Act as a flame barrier, preventing fire entering ductwork.

- Should be washed once a month in soapy warm water.

Electrostatic precipitator (ESP)

- ESP treated air is very clean: fitted in-duct to provide secondary filtration of grease, smoke and sub-micron particulates

- Has high air resistance

- Air enters ionizing section where a strong electric field charges any particles

- Air then passes in to a collection section where the charged particles are attracted to oppositely charged plates

- Plates must be removed and cleaned every month

Do I need odour control?

This depends the local authorities planning requirements, type and volume of cooking, surrounding area and discharge. A high level discharge may be sufficient on its own, but for low-level exhausts (i.e. street level) additional odour control will almost certainly be required. See DEFRA Odour risk assessment, Annex C, page 95.

High level, high velocity, high dilution

- Primary odour control, very effective

- Low air resistance

- Can be visually intrusive

- Duct requires cleaning annually

- Dilute smells with fresh air and then exhaust high up, at high speed (greater than 12 m/s, 28 mph) to ensure low-concentration dispersal over a wide area

Odour neutralising chemicals

- Additional odour control

- Very low air resistance

- Compact

- Expensive chemicals need refilling monthly

- Negatively charged odour neturaliser chemical is injected in to the duct

- Chemical is attracted to positively charged odour

Activated carbon filters

- Additional odour control

- High air resistance

- Very large, several units are needed to achieve sufficient contact/dwell time (>0.24 seconds)

- Pre-filters and carbon panels need replacing quarterly, high temperatures reduce life, so running cost can be expensive

- Cannot handle dust, grease or fine particulates, so must be protected with a pre-filter

- Activated carbon charcoal is used in gas masks to remove fumes and odours

Ultraviolet O-Zone

Ultraviolet O-Zone

- Additional odour control

- Medium air resistance

- Medium size, can be located remotely (out of air flow)

- UV fluroscent tubes need replacing every few years

- UV tubes convert oxygen in to ozone and hydroxyl free radicals

- These react with odour and grease through ozonolysis, leaving mainly carbon dioxide and water

- A long duct run is required for sufficient dwell time (2 seconds)

- Excess ozone is poisonous so shorter duct runs may need carbon filters to absorb it

Anti-vibration mountings and flexible connectors

- Prevents transmission of vibration, oscillation and resonance

- Fitted by Far East as standard

In-line dynamic attenuation silencers

- Attenuates noise travelling through the air stream in the duct

- Fitted after the fan, if required.

- Can also be fitted before the fan to reduce sound travelling back to the kitchen

Low level discharge

- Simple wall grill exhaust

- Very discrete

- More likely to create an odour nuisance

- Normally requires expensive additional odour control

Camouflage

- Run ducting internally as much as possible and place plant equipment inside

- Disguise any external ducting and plant with matt paint or cladding

- Internal mounting is expensive, slower and messy

- Access for cleaning and maintenance can be difficult

- Internal ducting may require fire dampers or fire proofing when it passes between floors